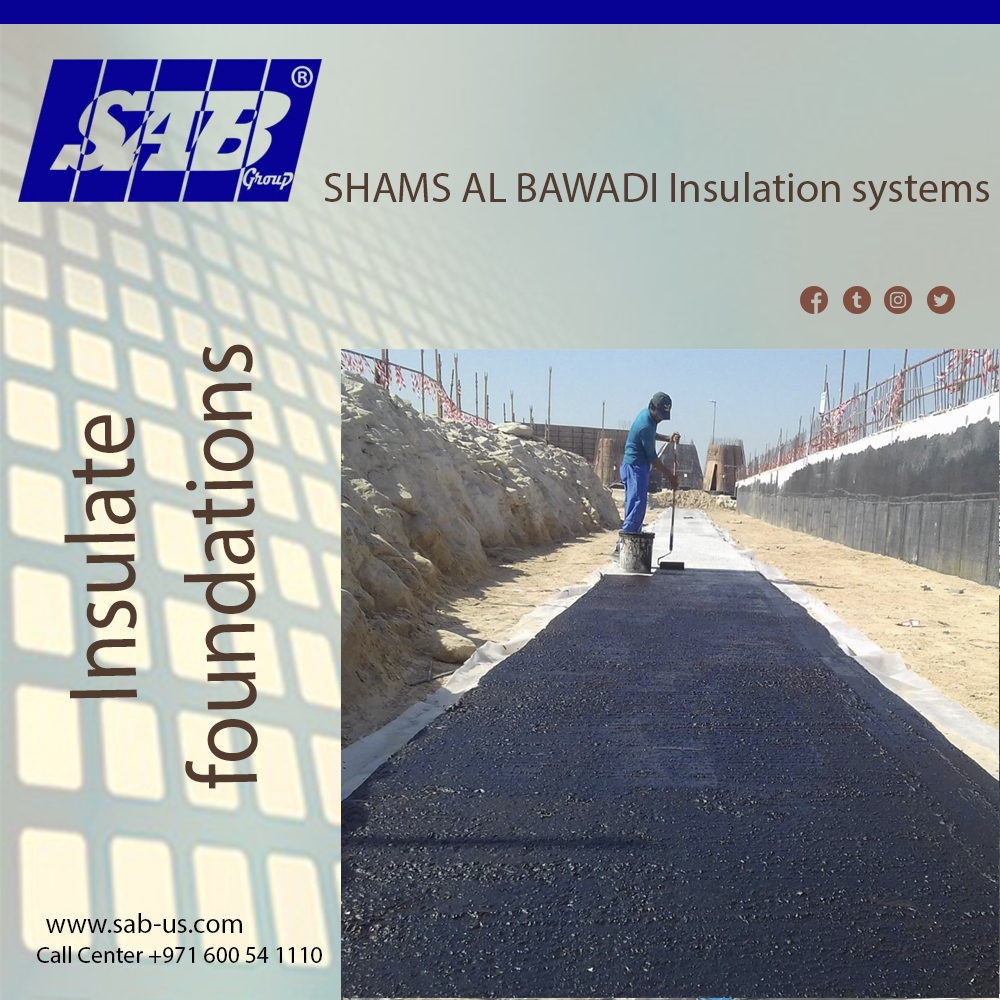

SAB® Substructure One Layer

One coat of cold Bituminous Primer

One layer 4mm thick SBS Membrane

- Terms & Conditions

- Prices excluding VAT.

- Prices excluding delivery costs

-

Delivery: 2 working days, (Weekend Friday, Saturday and Sunday)

Method of Statement

for Substructure Waterproofing works

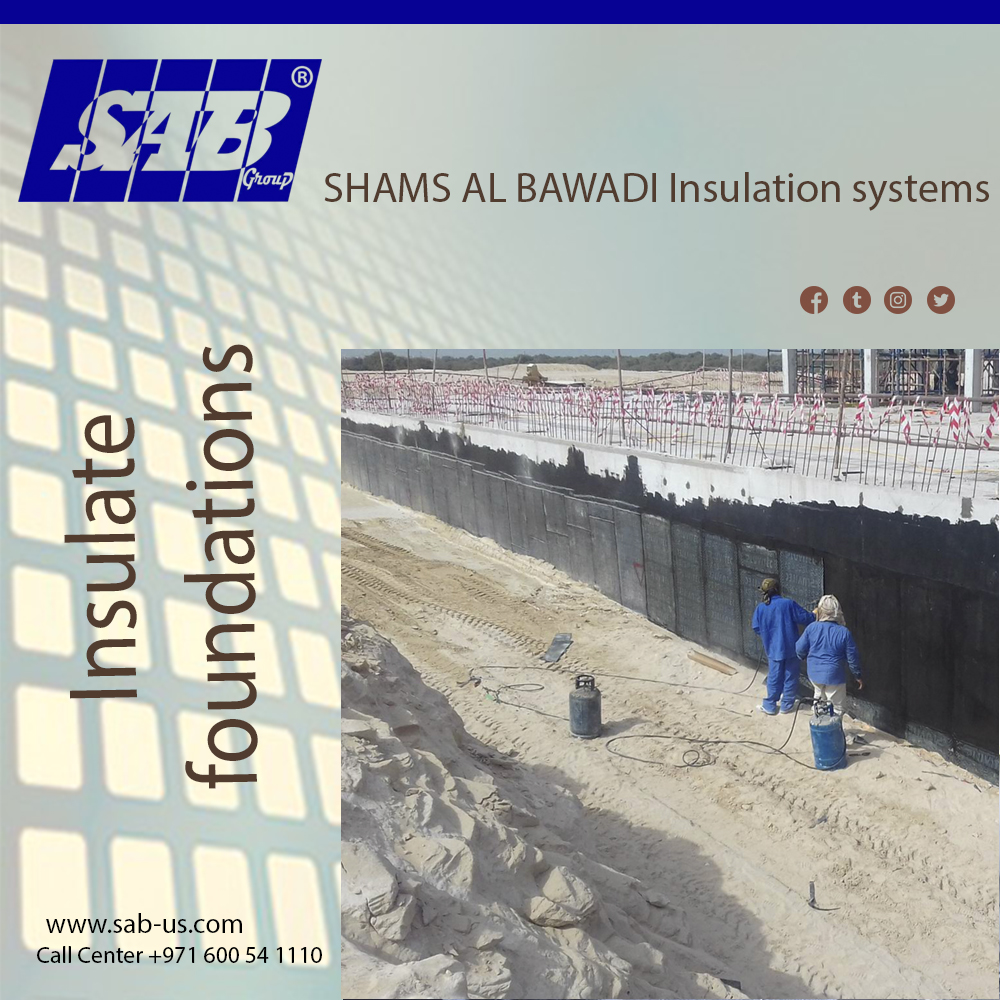

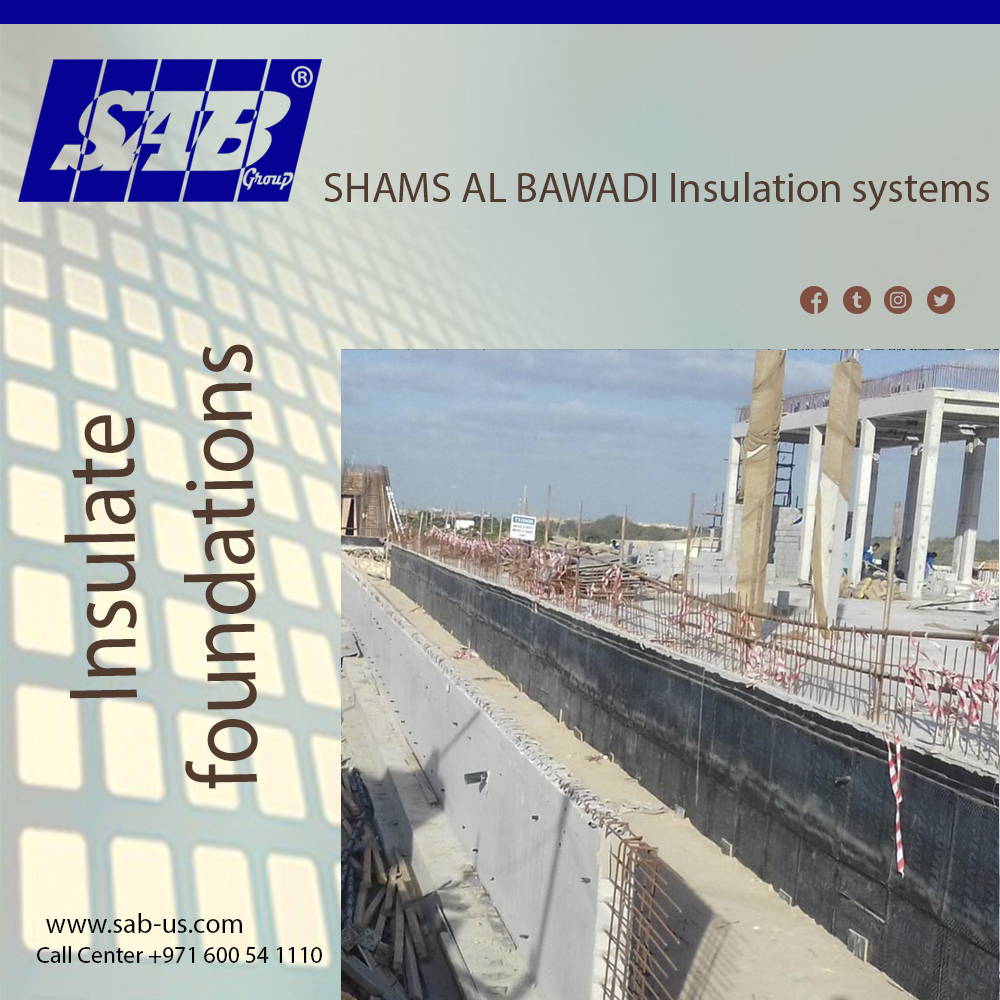

The motive of the technique declaration for utility of waterproofing is to stop the water to percolate or penetrate into any underground concrete members. When the water penetrates into the sub-grade concrete-like basis such as mat foundation, footing, tie beam, etc. the metal reinforcement that embedded in the concrete would corrode due to a chemical response precipitated with the aid of water and the shape would in the end fail.

Application of waterproofing particularly for giant constructions would have to be strictly supervised via a excellent engineer in order to stop failure of software or nonconformity to the pleasant procedure.

In this technique announcement for utility of waterproofing membrane, we’ll be going to use the membrane kind waterproofing, this kind of waterproofing is beneficial for buildings like high-rise constructions which has a deeper basis the place water strain is extraordinarily high.

Scope of Works.

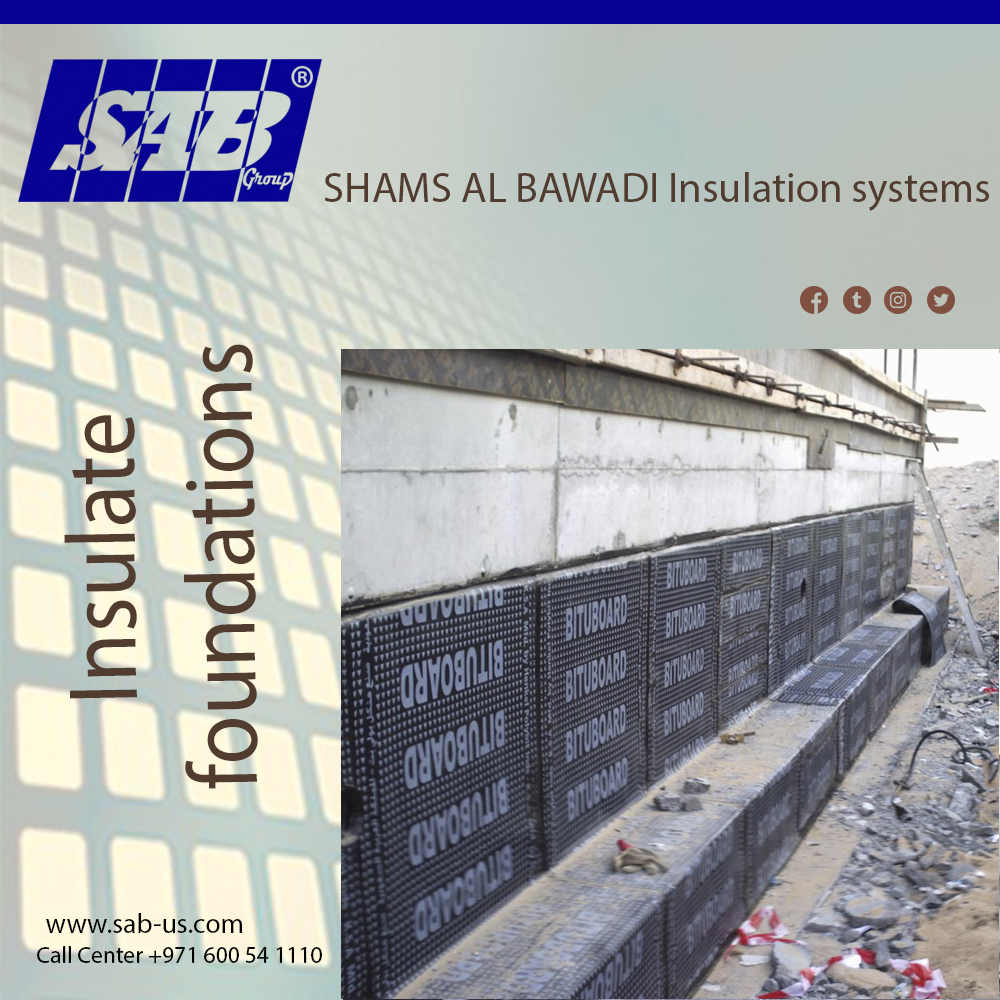

Install Double layer of 4mm thick SBS modified bituminous membrane bolstered with 180g/m2 non-woven polyester.

Unroll and role the membrane roll. Roll out half of a roll length, heating the underside of the membrane with the fuel flame till the polyethylene movie and bitumen mass melts.

Unroll the membrane step by step and continuously. A bead of liquid bitumen need to be seen on the

underside of the roll. The torch on membrane need to be firmly pressed onto the substrate in order to

avoid air entrapment the use of a curler or heavy brush.

Repeat this system with the 2nd 1/2 of the roll.

The membrane shall be torch utilized unfastened laid with 100mm broad overlaps.

Suggested alternatives: Compare