SAB® Profile 2023

المشاركة على مواقع التواصل الاجتماعي

مشاركة الرابط

استخدام رابط دائم للمشاركة في وسائل الاعلام الاجتماعيةالمشاركة مع صديق

برجاء تسجيل الدخول لإرسال هذا document بالبريد الالكتروني!

تضمين في موقعك

Step# 13

step#14: filling the expansion joints by: sponge then mastic .

Step#7: screed casting.

Step#8: screed softening by the helicopter.

Step#9 : expansion joints execution, SIZE: 20 cmx20cm.

Step#10: Removing the flexible sheets.

Step#11: filling the expansion joints by: sponge then mastic.

Step#12: Acrylic application (top coat).

INTR O DUCTION :

SAB ® Insulation system has been established since 2004 in Ras Al Khimah – UAE, as a specialist company in waterproofing domain. During the past years our ambition and passion motivated us t o develop our performance in many important ways. We believe that in order to succeed we must face certain obstacles and challenges in our career. However we could during the few past years to become one of the certificated and qualified companies from most of ministries, government departments, and multiple of consultants.

We began as a small company having few members during the previous years we built our big family in very healthy environment and strong bonds with one principle and vision.

Strategically , our career forms part from society service, our major responsibility toward society is working as hard as possible. All appreciation and gratitude is given to UAE'S government and citizens for the great supporting.

Kassem Mohammed Ghatrif CEO

carefully, without causing any vandalism or damages in screed edges along with those flexible sheets that had been removed.

11. Filling the expansion joints by sponge 20mm thickne ss, then apply mastic coat minimally: 15mm height and 15mm width, to protect screed edges this forming important stage to avoid a high probability leaking in this weakness area.

12. Air conditions bases (main contractor responsibility) should implement on the top of the roof slab far away from expansion joints, this step should be before acrylic execution. Taking into consideration keeping the insulation system clean and safe.

13. apply (Acrylic) top coating, spray Applied, which transform from liquid texture duri ng application into elastic and flexible coating when drying , and its specification : highly flexibility, Weather resistant, and High adhesion power IMPORTANT NOTE:

•The above mentioned insulation system is thermal and moisture protection system.

•SAB ® Tron insulation system guarantee is for 20 years only.

Step #1: Roof preparation.

Step#2: polyurethane application.

Step#3: Cold Rubbrize application.

Step#4: Water testing. Step#5: Separation layers application.

Step#6: Ridges execution.

Step#7: applying cold bituminous primer

Step#8: Install one layer APP elastomeric membrane.

Step#9: Water testing..

Step#10: Ridge execution . Step#11 screed casting

step #12: screed softening by the helicopter.

SAB ® insulation Methodology Clarification, (support ed by SAB ® archive photos).

Step#1: Roof preparation, threshold placement.

Step#2:Roof preparation, parapet A/C pipes. S S tep#3: Roof preparation, middle A/C pipes.

Step#4: Roof preparation, electrical conductors are well sealed .

Step#5: slop corners 20x20 cm along with the parapet.

Step#6: 1.5x1.5 cm execution along the parapet.

Quality System Procedure “ SPRAY APPLICATIO N PROCEDURE”

1. Purpose: INTRODUCTION

WHAT IS POLYURETHANE?

It is the first step in the Combo roof system which is providing thermal and moistures protection.

A chemical reaction will happen when two liquid components are combined at the tip of a gun. W hen the two parts are combined in the spray nozzle, they start a chemical reaction that creates the foam. Within seconds, the liquid is on the roof surface has expanded to 20 times its original mass, within minutes this foam can be walked on and cures to 9 0 percent of its full strength in about four hours. The purpose of this quality system procedure is to ensure that:

All polyurethane application procedure documents are controlled , reviewed and approved prior execution.

All records are available with evidence.

Polyurethane process are matching with the required measurements and specification according to: BS EN 14315 1 2013

Achieving polyurethane main purpose as an advanced waterproofing method.

Ensuring professionalism and consistently provide product s that meet customer and applicable statutory and regulatory requirements, and aims to enhance customer satisfaction. By providing conforming product and continuous improvement and the prevention of nonconformity.

2. Scope Installing waterproofing insulation system. This type of insulation system forms a thermal and moisture protective system; it can be applied either on a concrete slab or any other surface with any shape or size. This material has many properties which can be summered as follows:

All raw materials must be received either in site or warehouse should be attached with certificate of analysis and take into consideration this procedures must be fallen with any each delivery in order to ensure that the expiry date is matching with our requirements of 6 months. In case the received materials were expired we have to start goods return procedures and making official complaint to the concern supplier, and send supplier evaluation form.

Determine criteria and methods required to ensure the effective operation and control of these processes by:

• Ensure the availability of information necessary to support the operation and monitoring o f these processes

• Measure, monitor and analyze these processes

• Implement actions necessary to achieve the planned results and continual improvement: To ensure the above points we should follow the below instruction :

• Install all materials in strict accordance with all published safety, weather, and temperature precautions given by the manufacturer.

• Foam normally shall not be applied when the measured roof deck temperature is below 50°F (10 °C ), or above 120°F (48 °C ).

• Foam shall not be applied when the relative humidity is above 85%.

• Foam shall not be applied when wind velocities exceed 12 miles per hour, as measured by a wind velometer, as well as wind direction.

• Application of spray foam shall not commence during inclement weather or when precipitation.

• Foam shall not be applied to any surface where visible moisture is present or, when tested with a moisture meter, registers a reading greater than ten percent.

Process conditions clarifications: Machine Conditions Mix Ratio of Components 1 : 1 ( by volume ) Component Temperatures 30 – 50 degree C Component Pressure 50 – 80 bar Hose temperature maximum 90º C / 194 F Hose heating power maximum 50 Amps Hose length maximum 93 m Environment conditions Ambient Temperature between +10 an d +45 degree C Relative Humidity Less than 85% Wind speed Less than 30 km/h

STANDARD SPECIFICATIONS ACCORDING TO SAB® INSULATION SYSTEMS: C. SAB ® Ro of Insulation System/ Balconies, Kitchens, and Toilets. Recommendations:

1. Water pipes should be placed in place and minimally on height 4 cm.

2. Water pipelines should be installed very carefully above insulation layers, without causing any damages or vandalis m.

3. Wet area insulation layers must be implemented, when all ceramic (walls)installation has been completed.

How to implement wet area insulation layers:

1. As a preparation for perfect result these procedure must be taken into consideration: Cleaning the su rface properly and make sure the surface is free of dust or debris as well as ground settlement. 2. Execute slope corners 20cm * 20cm.

3. Applying 2 layers of SAB ® Creet.

4. Water testing should be by using sweet water ,for 24 - 48 hours, this water test will give hig h opportunity to discover any leakage might be happen, either it was due to manufacturing defect or poor quality materials,( this procedure should be on the main contractor responsibility, and under consultant engineer supervision).

5. Upon completion from al l waterproofing works and installing water pipes on its places, as a precautionary action form any further leakage or vandalism , all insulation materials must be covered by sand / 03 which will be used during ceramic execution.

6. We do recommend and advise ceramic applicators to use flexible and water resistance mortar properly while installing ceramic (floor) and the tub, these materials would support and complement our works.

SAB ® Roof guarantees is valid for 5 years.

• General observations and visual surface inspection

• Thickness testing

• Physical sampling by: Qualitative analyses and testing in the lab.

General observations and visual surface inspection:

There are many documents should be recorded before polyurethane foam application which must be daily basis the follows is showing an example of the required information.

• Project Characte ristics.

• Building location.

• Scope of work

• Date of execution.

• Supplier’s name

• Products name and classification.

• Batch number for each application. Visual Observations: Visual observations are those that can be seen with the naked eye such as:

• Cracks and shrinkage: Are characterized as cohesive failure, the approximate size and numbers must be recorded.

• Surface Appearance Surface texture will fall under one of the following labels:

1) Smooth

2) Orange Peel

3) Coarse Orange Peel

4) Verge of Popcorn

5) Popcorn

6) Tree bark Numbers 5 - 6 are not acceptable. They must be removed.

• Gaps: are unintentional openings in the thermal envelope which may permit excessive heat transfer

• Mechanical Damage Any vandalism should be considered as a defect and must be reported immediately.

• Color: exposure to Ultra - violet radiation (such as from sunlight) causing a change and darken the surface, whereas the interior mass is not affected. Then the surface tends to turn an orange color. The surface typical ly becomes dusty and friable.

As a result, UV rays affect the adhesion and losing the foam thickness. That means the polyurethane is not acceptable.

Thickness Testing By taking thickness measurements at a variety of high and low locations. BY USING CALL IPER Physical sampling: by providing samples 10cm*10cm to be testing in the lab.

Pre preparations • Conduct a pre - job assessment so that health and safety risks can be identified and managed. Special hot or cold working conditions.

• Review environmental conditions, (air and surface temperature, relative humidity, surface moisture, and wind speed) to ensure that they are appropriate for polyurethane foam application.

• Establish a safe work zone around the polyurethane foam application.

• Providing a safety tools like eye wash or cleansing wipes if tap water is not accessible at the jobsite. As well as mask to prevent breathing chemicals, vapors, and/or dust. Also other safety requirements should be available like gloves, head coverings, and foot protection.

• Use equipment that is clean and well maintained.

• Ensure that chemical drums, hoses, and other equipment are warmed up to the proper temperature before use, as per manufacturer guidelines. Ensure that proper equipment settings (e.g., pressure, temperature,) are used.

• Perform a small test spray and check foam quality after five minutes. Make any necessary equipment adjustments.

Handling breakdown: The storekeeper and the management representative should maintain maintenance and calibration register we ekly basis, this procedure must be communicated to all concern crews before spraying, to avoid any breakdown.

Paying high attention to the control panel unit that will prevent exceeding pressure and temperature more than safety limits, in this case the observer should start breakdown process and communicating with authorized person. ALARMS procedure:

• Check the electrical supply connections

• Check the product pressure.

• Check the heater heating system. To avoid breakdown there are many precaution must be taking into consideration:

• To prevent all possible bodily harm, all applicator must follow safety procedures through wearing gloves, protective goggles, and safety footwear and face masks. Use breathing equipment when working with the machine i n enclosed spaces.

• Handling of the raw materials should be very carefully.

• Disconnect the unit from the power supply before carrying out any operation inside the electrical console.

• The electrical maintenance of the machine must only be performed by a qualified electrician.

• To avoid damage caused by the impact of pressurized fluids, maintenance work should not be performed on components until the pressure has been completely eliminated.

• The unit includes components that reach temperatures that are liable to cause burns. The hot parts of the unit must not be handled until they have cooled.

• Fire extinguisher must be available for any moments as well as the first kit aid.

Application following up and inspection: Generally, polyurethane insulation inspections follow a multi - step process with each step documented through observation, photography and commentary as follows:

A / SAB ® Tron – Combo system, (Integrated insulation System) / Roof.

1. Clean the roof slab from all dust or debris by using compressed air, directly before Polyurethane implementation.

2. Applying polyurethane foaming spray, averagely: 35 - 40 mm thick & 40 - 48 m 3 densities (or as requirements).

3. water testing should be by using sweet water ,for 24 - 48 hours, this water test will give high opportunity to discover any leakage might be happen, either it was due to manufacturing defect or poor quality materials, this step can be after polyurethane or after rubberized application ( this procedure should be on the main contractor responsibility, and under consultant engineer supervision)

4. Applying one coating of cold liquid elastomeric modified Bitumen Rubberized Emulsion, which is water based, and Non - flammable. (Application should be by brush). 5. covering all the above mentioned steps by using one layer of non woven polyester synthetic fabric filter membrane (Geotextile Separation Layer 100gm/m 2 )

6. Dividing the roof slab into multiple squares (its area is 300cm * 300cm), then execute ridges by using the flexible sheets with thickness 12mm, and its height is matching with roof slope 1/100 (that will increase 1 mm height for each 1m length), taking into consideration the water pipe will forming the starting point to execute ridges in this stage, and its screed should be at 4 cm minimally .

7. Casting screed of Ready Mix Concrete – 300 OPC, 20 N. (or as requirements).

8. Soften the casting ready mix concrete by using the helicopter, this procedure should be on the same casting day and when the screed starts to be dry.

9. Execute slope corners 20cm*20cm to cover the upper side of insulation layers along with the parapet, in order to avoid a high probability leaking in this weakness area.

10. Approximately 5 days later, be sure the casting screed ready mix concrete is well dry, than all flexible sheets must be removed very

OPTIMISATION METHODOLOGY TO IMPLEMENT THERMAL & MOISTURE INSULATION

The Contractor is referred to the Specifications and Drawings for all details that are related to this Section of the Works, in order to insure full commitment with all the requirements contained the rein, thus the thermal & moisture insulation will reach to the required professionalism and effectiveness. Perquisites required from Main Contractor:

Insulation works should be implemented by specialized company and should be approved from the consultant; as well it should have minimum 5 years' experience.

Electrical conductors and water pipes should be sealed properly, to avoid any water leakage.

Water rain pipes should be in place at specific height (approximately 3 cm), according to roof slope.

Parapet should be plastered to the required height, (after 25 cm Vertical from the roof slab).

The threshold either for door or staircase, as well as dome holes should be in place and at specific height approximately 25 cm, (in case of existing).

All electrical conductors or other pipes might be existing in the middle of roof slab, should be passing through sleeves and on 35 cm minimally height. , these sleeves will support replacement procedures in case of further maintenance for these conductors are required.

Parapet AC or water pipe connectors exits should be passing through sleeves should be in place at minimum height of 35 cm.

Insulation system is very delicate and important task, that's will make the main contractor is responsible to ensure full co - operatio n and attention from other subcontractor's whom their scope of works will start after waterproofing systems such as AC, water pipe, water tanks, ,...etc.,

in order to avoid any damages or vandalism in insulation layers either partially or totally.

Following up the above mentioned notes and the below methodology will avoid further maintenance.

Implemented company must issue guarantee letters (defects liability period), for all insulation works, this guarantee will be use during any maintenance, taking into consideration guarantee period.

Puncture the insulation layers under any circumstances is not allowed, this will cause leakage either currently or later on.

STANDARD SPECIFICATIONS ACCORDING TO SAB® INSULATION SYSTEMS:

B - SAB ® Pro111 Insulation System/ Roof .

1. The threshold either for door or staircase,'' in case of existing'', should be on place and at specific height approximately30 cm.

2. Ac pipes& water which been placed on the parapet, must be lifted up and higher then insulations layers.

3. Ac pipes which been existed in the middle of the roof slab, must be lifted up 40 cm.

4. As preparation before starting insulation system, roof slab should be smoothening .

5. Execute slop corners 20x20 cm along with the parapet, to avoid the sharp area along the roof.

6. Cavity 1.5x1.5 cm must be executed along the parapet, and directly over the slop corners, this cavity will protect the membrane edges from any vandalism or climate, as well as this cavity will work as barrier to inhibit water leaking in this weakness area when membrane edges are placed.

7. Applying one coat of cold bituminous primer 350g/m 2

8. Install one layer APP elastomeric membrane 4 mm thickness, reinforced with 200 g/m2 non - woven polyester including overlaps 10 cm.

9. Water testing should be by using sweet water ,for 24 - 48 hours, this water test will give high opportunity to discover any leakage might be happen, either it was due to manufacturing defect or poor quality materials, ( this procedure should be on the main contractor responsibility, and under consultant engineer supervision) .

10. Dividing the roof slab into multiple squares (its area is 300cm * 300cm), then execute ridges by using the flexible she ets with thickness 12mm, and its height is matching with roof slope 1/100 (that will increase 1 mm height for each 1m length), taking into consideration the water pipe will forming the starting point to execute ridges in this stage, and its screed should b e at 4 cm minimally .

11. Casting screed of Ready Mix Concrete – 250 OPC, 15 N.

12. Soften the casting ready mix concrete by using the helicopter, this procedure should be on the same casting day and when the screed starts to be dry. 13. Execute slope corners 20cm*20cm to cover the upper side of insulation layers along with the barbate, in order to avoid a high probabilit y leaking in this weakness area . 1. Approximately 5 days later, be sure the casting screed ready mix concrete is well dry, than all flexible sheets must be removed very carefully, without causing any vandalism or damages in screed edges along with those flexible sheets that had been removed. Then filling the se expansion joints by sponge 20mm thickness, then apply mastic coat minimally: 15mm height and 15mm width , to protect screed edges this forming important stage to avoid a high probability leaking in this weakness area. **** Air conditions bases (main contractor responsibility) should implement on the top of the roof slab far away from expansion joints, t his step should be before acrylic execution.

IMPORTANT NOTE: •The above mentioned insulation system is moisture protection system . •SAB ® Pro111 insulation system guarantee is for 10 years only.

Verify field measurements .

Verify receiving the required material s according to the LPO.

Reporting / recording any non - conformity that might exist. Manpower (Mp):

Crews must be aware about scope of work generally, and about requirements, specification and procedure classification especially.

Crews are ready to start w ork , in order to ensure that work begins only when they verify that conditions conform to the project quality requirements.

Crews must be aware about safety rules. 4.0

Procedure : General Requirements

• Determine the sequence: ROOF PREPERATION :

• Electrical conductors and water pipes should be sealed properly .

• Water rain pipes should be in place at specific height

• Parapet should be plastered to the required height.

• The threshold either for door or staircase, as well as dome holes should be in place and at specific height (in case of existing).

• All electrical conductors or other pipes might be existing in the middle of roof slab, should be passing through sleeves .

These sleeves will support replacement procedures in case of further maintenance for these conductors are required.

R oof slab is well cleaned from all dust or debris. Safety advice

Protective clothing, safety goggles and impermeable gloves must be worn while implementation.

Splashes in the eyes, must be thoroughly rinsed with plenty of water, parts must be washed then with soap and water.

Contaminated clothing must be changed daily bases.

One of the consequences of non - observance of the safety advice could be allergic reactions.

Storage and delivery Products must be protected from moisture.

Can be kept for at least six months at 15~30°C in hermetically sealed drums.

Products should not store for long periods at temperatures below 10°C, because it may be able to lead to an excessive increase in viscosity, particularly if moisture has access to the product.

Products must be receiving according to purchase procedure and in good conditions.

STANDARD SPECIFICATIONS ACCORDING TO SAB® INSULATION SYSTEMS:

Index

A SAB ® Tron – Combo system, (Integrated insulation System) / Roof.

B SAB ® Pro111 Insulation System/ Roof .

C SAB ® Roof Insulation System/ Balconies, Kitchens, and Toilets.

d SAB ® Crystal 410 Insulation System / Water Tank

E SAB ® Active Insulation System / Maintenance old building

F SAB ® 3 Action Insulation System / Aluminum roof

G Integrated insulation System / Towers' Foundations.

H Foundation Waterproofing/ Small Enterprises.

I Pile Waterproofing.

Seamless: Polyurethane foam is applied as a liquid, creating a single close celled monolithic membrane that covers the entire roof.

Flexible: The foam can be sprayed onto virtually any surface, irregularly shaped roofs.

Lightweight: Foam roofing typically weighs around 50 lbs. per square, moreover it is ideal for aluminum suffice.

After polyurethane application, the solid surface is now high water resistant. Its high insulation reduces heat penetration which boosts the buildings overall. POLYUERTHANE is designed to provide a high performance .

03. Responsibilities

TERMS & DEFINITIONS

MR Management Representative

MG General Manager

PE Project engineer

PUR Purchase head department

PS Project supervisor.

MP Manpower

Management Representative (MR) :

Is responsible for the document and data control .

Maintain and control all the related records. Uncontrolled documents will not be updated. General Manager ( GM ):

Responsible for the approval .

Responsible for reviewing the documents before issuance . Project engineer (PE) :

Prepares/reviews the site requisitions and materials specification. And officially communicate with head of purchase order regarding materials orders.

Ensures that material submittal schedule is followed.

Ensure that equipment meet t he requirements and availability of manpower.

Follow up application sequence. Follow up any non - conformity might be arising and determine the corrective action. Purchase head department (PUR):

Issue the LPO based on project specification that had been previously communicated.

Recording delivery based on our purchasing procedures.

Project supervisor (PS):

Assesses completion of required prior work , to ensure the surface preparation is done.

DESCRI PTION SAB ® Crystal 410 is a unique sealing compound designed to expand rapidly when exposed to moisture making it a self - healing joint material for construction joint applications. RECOMMENDED FOR Typical Applications for Penebar SW - 45 Rapid include build ing foundations, slabs, retaining walls, storage tanks, and similar non - moving cold construction joints.

SAB ® Crystal 410 methodology

This system is made of 2 materials:

SAB ® Crystal 410 concentrate and one more other supporting material.

As preparation:

Cleaning scope of work area properly.

Spraying the outer side with water, the Property of this material it needs wet area to make the required strong interaction.

Puncture the surface by making tiny holes, this will ensure perfect absorption.

Cleaning the se small holes and insures it dry; taking into consideration the whole area is still wet.

How to implement: Mixing SAB ® Crystal 410 concentrate with desalinated water, in this standard : each one amount of water requires three amounts of this material. T he blended quantity should be using within 30 minutes. Then we start to fill the holes with this mixture and smoothing these holes to be matching with the whole surface.

Treat ing the joint area between water tank ground and walls.

As final step: implement the supporting material over these holes within 6 hours at latest.

SAB ® Crystal 410 specification:

After professional performing this system will form integral part from the concrete slab even in slab crash cases.

Its implementation could be on any concr ete slab sides.

Water proofing system and having high resistance against chemicals materials.

Effective against hydrostatic pressure.

Easy to apply with shortage time and co st.

Doesn’t weaken the concrete or breaking it.

Doesn’t need any extra protection after execution.

Minimizing the existing cracks.

Non poison as well as eco - friendly. So it is safe to be used as a waterproofing material inside or outside the water tank.

Protect the concrete slab and the inner supporting iron.

Lightweight materials more over, it can be used even on an old concrete without adding an extra weight. While in other insulation system we have to consider this matter specifically.

INDEX page Description 2 INTR O DUCTION.

3 VISION, MI S SION AND VALUE.

4 O RGANIZATIONAL CHART.

5 COMMERCIAL LICENSES. 8 DUBAI MUNICI PA LITY. 1 0 TRADE MARKS 1 2 ISO 1 5 MOPW APPROVAL 29 COMMAND OF MILIRITARY 3 3 GONERNMENT OF AJMAN 3 5 CONSULTANT APP ROVAL. 4 3 V E NDOR LIST. 5 1 COMPLETION CERTIFICATE. 6 4 AWARDS 7 2 SUPPORTING SOCIETY 7 5 SUPPLIER CERTIFICATE 7 8 OPTIMISTICTION METHODOLOGY TO IMPLEMENT THERMAL – MOISTURE INSULATION 9 3 SAB TRON GREEN BUILDING SECTION 9 4 PU SPRAY APPLICATION PROCED URE 10 3 PREVIOUS WORKS

technical supervisor. marked by paint, tape, tag, or other easily observable signal to prevent inadvertent cover - up. PREVENTIVE record. And nonconformance report. CONTROL THE CONTINUATION OF WORK After the problem is marked, the inspector must determine either work can continue in the affected area or not. CONTINUE WORK: When the problem have been resolved, based on that work does not affect quality or hide th e defect Refer to CORRECTIVE AND PREVENTIVE record. And nonconformance report. STOP WORK ORDER , and keep it on hold unless the problem had been cleared and solved. Refer to CORRECTIVE AND PREVENTIVE record. And nonconformance report. RECORDING OF NONCONFORMANCES The problem is not solving. sending the nonconformance report to the Quality Manager Refer to CORRECTIVE AND PREVENTIVE record. And nonconformance report. COPMLETION After the problem had been solved Resuming execution and Handling over the project. Refer to project plan record

Marks:

Make sure that the materials are matching with project material’s specification.

Do not apply POLYURETHANE foam if weather conditions will not permit it to achieve its effective purpose.

Technically, the machine should be under maintenance monthly bases to ensure its function meets the requirements. Additionally, manpower must be qualified.

Practically, the used materials must be of high quality in order to meet waterproofing purpose.

The thickness of each applied layer should be between 1 and 1.5 cm if layers are too thick, overheating may occur, which can damage the foam; and result off - gassing, and shrinkage. So it is not recommended to apply thick layers Allow sufficient cooling time before applying additional layers, particularly for closed cell foam. We recommend 20 minutes to allow heat to dissipate. Caution shall be taken to protect those areas not to receive spray foam, including vehicles located nearby.

Spray ed area shall be kept protected during and for twenty - four hours after completion of application

. PROCESS STAGE INSPECTION & TESTING NAME RESPONSIBLE PERSON RELATED PROCEDURE SAMPLE SIZE ACCEPTABLE RESULT PREPARATOY SITR INSPECTION Assesses completion of required prior work Name of project supervisor. Project supervisor Starting execution, due to there is no obstacle recorded Task inspection results will be recorded on the Work task Inspection Form Verifies field measurements Name of project supervisor. Project supervisor Starting execution, due to there is no obstacle recorded Task inspection results will be recorded on the Work task Inspection Form Assures availability and receiving the materials as per the specification Name of project supervisor. Project supervisor Starting execution, due to there is no obstacle record Task inspection results will be recorded on the Work task Inspection Form Identifies any nonconformance to the requirements before starting. Name of project supervisor . Project supervisor Identify problem root, then set up corrective plan. Refer to nonconformance report. Identifies potential problems Name of project supervisor. Project supervisor Identify the problem that might rise, and Refer to massage out file. And preventive record

communicate with the client . TASK - READY INSPECTIONS Crews are ready to start work and ensures that work begins only when they verify that conditions conform to the project quality requirements. Name of project supervisor. Project supervisor Starting execution, due to there is no obstacle record Refer to training needs assessment and daily work distribution WORK IN PROCESS QUALITY INSPECTIONS The first step of a work activity is completed. According to inspector performs, wo rk will keep ongoing in process and ensure that work activities continue to meet project quality requirements. Name of project supervisor. Project supervisor Starting execution, due to there is no obstacle recorded Daily inspections of work in process will be recorded on the Daily Quality Control Report. WORK TASK COMPLETION QUALITY INSPECTIONS Completion of each work task to verify that work conforms to project quality requirements. Name of project supervisor. Project supervisor Starting execution, d ue to there is no obstacle record Daily inspections of work in process will be recorded on the Daily Quality Control Report. MARKING OF NONCONFORMANCES AND OBSERVATIONS Specifying the problem root. Name of Project engineer and Project engineer and technical supervisor. The problem should quickly and clearly Refer to CORRECTIVE AND

61 Substructure / commercial building G+3P+ 15 TYPICAL Dar Alomran GULF SKY Eng Consultant& Project Management. Mr . Abbas Chou. SHJ 2,534 M 2 62 Gems School / roof – wet area - water tank NEB/ National Engineering Bureau Emirates General Contracting LLC Dr. Suleiman Moosa Al Jasim FUJ 4 , 601 M 2 63 Residential& commercial building G+3P+2M+20+PH+HC Wet area - roof - substructure Al Qalaa Engineering Consultant Delta Building Contracting Mr. Sohail Shaheen FUJ 7,200 M 2 64 Dubai Crocodile Park Eng. Adnan Saffarini Office Becon Construction White Oryx Dubai 7,617 M 2 65 Commercial Building Eng. Adnan Saffarini Office Al Sarh Co ntracting M/S Syann Park 1 Limited Dubai 900 M 2 66 Parking Al Anfal Abdulla Al Muhairi Mr. Ahmad Al Ramthi Dubai M 2 67 Private Villa Lacasa Commodore Contracting Co L.L.C Mr. Hussain Sejwani Dubai 1,900 M 2 68 Sillicon Gate 1 ( Sillicon Oasis ) Time Prop erties Time Properties Time Properties Dubai 1,900 M 2 69 Residential& commercial building G+3P+ 11 + epuohtnep Barajeel Engineering Consultant milnSunB ilA Private inb l 2,209 M 2 01 185 National Housing Ministry of Infrastructure Development ASWAR ENG & GE N CONT CO L.L.C. ART OF ARCHITECTURE Engineers Consultants SHJ 34,841 M 2 01 60 National Housing Ministry of Infrastructure Development JIANGSU JINGTIAN BUILDING CONTRACTING ART OF ARCHITECTURE Engineers Consultants SHJ 15 , 730 M 2 07 Residency And Foreign Affairs Ministry of Infrastructure Development ASWAR ENG & GEN CONT CO L.L.C. Design Center Architects & Engineers Consultants SHJ 8 , 511 M 2 03 741 National Housing Sheikh Zayed Housing Programme ASWAR ENG & GEN CONT CO L.L.C. Sheikh Zayed Housing Program me Rak 47,000 M 2 The executed projects mentioned above represent a brief example of our career.

32 Masjed Internati onal Engineering Consultant Obaid Al Mazroie Dubai Municipality Rak 1,700 M 2 33 ABID International Engineering Consultant Al - Islah Contracting ABID RAK 2,900 M 2 34 Expo International Engineering Consultant Al Hael RAK Chamber of Commerce RAK 2,900 M 2 35 Majlis HH Sheikh Mohammed Home of Architecture Al Taameer HH Sheikh Mohammed RAK 3,200 M 2 36 Commercial Building 10 floors International Engineering Consultant Two Construct Joma Al Zouabi RAK 3,500 M 2 37 Masjid HH Sheikh Sultan Al Qasimi Internationa l Engineering Consultant Two Construct HH Sheikh Sultan Al Qasimi RAK 4 ,000 M 2 38 I TTIHAD UNIVERSITY International Engineering Consultant Two Construct Government of RAK RAK 4,800 M 2 39 Water Tanks International Engineering Consultant Quba General Contra cting Emirates Block Factory RAK 600 M 2 40 Police Storage Area Al Emaar Al Jazeera Civil Engineering Ministry of Interior RAK 2,600 M 2 41 Masjid Gulf Engineering Group Cyclone contrcting General Authority of Islamic Affairs Rak 2,450 M 2 42 Ain Khat Reso rt Hisham Al Laham Al Hamra Construction Government of RAK RAK 950 M 2 43 Apartment complex 6 villas Aber Al Emirates Al Saif Al Thahabi Said Al Bahhar RAK 1,200 M 2 44 Al Bourj Plastic Factory Al Zein Design Eng & Consultants Al Jazeera Civil Engineering Investors RAK 950 M 2 45 Commercial Building 5 floors Bit Al Emirates Concord Mohammed Al Saadi RAK 950 M 2 46 Commercial Building 7 floors Emco Engineering Consultant Obaid Al Mazroie Marshal Khalfan Al Ramthi RAK 900 M 2 47 RAK Airport Shine Marine RAK Aviation Academy RAK 1,250 M 2 48 Private villa Bin Laden Fatema Bin Laden Dubai 700 M 2 49 Bin Laden Accommodation Hisham Al Baraha Bin Laden Bin Laden SHJ 2,500 M 2 50 Apartment complex 8 villas High Art Al Zahraa Marwan Abu Ghazala Dubai 3,600 M 2 51 Al Saeed Complex 10 villas Al Mostqbel Al Enshaat Al haditha Sami Kubaj RAK 2,000 M 2 52 112 National Housing Ministry of Infrastructure Development ASWAR ENG & GEN CONT CO L.L.C. Ministry of Infrastructure Development Khour fakkan 24,316 M 2 53 54 Nationa l Housing Ministry of Infrastructure Development ASWAR ENG & GEN CONT CO L.L.C. Ministry of Infrastructure Development Khour fakkan 9,863 M 2 54 52 National Housing Ministry of Infrastructure Development East Coast Contracting & Trading Ministry of Infrast ructure Development Khour fakkan 10,353 M 2 55 230 National Housing Ministry of Infrastructure Development ASWAR ENG & GEN CONT CO L.L.C. Ministry of Infrastructure Development Ajman 52,900 M 2 56 200 National Housing Ministry of Infrastructure Development A SWAR ENG & GEN CONT CO L.L.C. Ministry of Infrastructure Development Eastern Area 45,000 M 2 57 30 National Housing Ministry of Infrastructure Development AL NUAIMI GROUP Ministry of Infrastructure Development RAK 6,850 M 2 58 VETERINARY CLINIC Ministry of I nfrastructure Development Al Mummayaz Engineering Cont L.L.C. Ministry of Infrastructure Development Ajman 750 M 2 59 Water Tank In 182 Const of Al Hamra District Cooling Plant Home of Architecture ORION CONTRACTING CO RAK Properties RAK 1,305 M 2 60 Pil e Head Treatment / commercial building G+3P+ 15 TYPICAL Dar Alomran GULF SKY Eng Consultant& Project Management. Mr. Abbas Chou. SHJ 147 PILE

S.NO Project Description Consultant Main Contractor Client Location Area 1 Health Care Center Ministry of Infrastructure Development Al Moqaweloon Ministry of Health Shawka 1,600 M 2 2 Al Ramis School Ministry of Infrastructure Development Silver Jubilee Ministry of Education RAK 1,800 M 2 3 Nursery Ministry of Infrastructure Development Quba Contracting Ministry of Education RAK 1,900 M 2 4 Ministry of Public Works building Ministry o f Infrastructure Development Quba Contracting Ministry of Infrastructure Development FUJ 2,500 M 2 5 12 National Housing Ministry of Infrastructure Development Islamic Building Contracting Ministry of Infrastructure Development FUJ 2,520 M 2 6 Foreigners A ffairs Building Ministry of Infrastructure Development Aswar Engineering Ministry of Infrastructure Development Khour Fakkan 2,800 M 2 7 15 National Housing Ministry of Infrastructure Development Al Saleh Ministry of Infrastructure Development Sharjah 3,07 5 M 2 8 Extension WORKS Command of Military fAYA Command of Military RAK 4,800 M 2 9 24National Housing Ministry of Infrastructure Development Emirates General Contracting L.L.C Ministry of Infrastructure Development RAK 4,920 M 2 10 Observation Center Min istry of Infrastructure Development Al Twakoul HH Sheikh Saqer Palace RAK 850 M 2 11 Masjid / Ramis Ministry of Infrastructure Development Silver Jubilee Bld Cont L.L.C General Authority of Islamic Affairs RAK 1,550 M 2 12 8 National Housing Ministry of I nfrastructure Development Al Ofeq Contracting L.L.C Ministry of Infrastructure Development UAQ 1,200 M 2 13 Culture Center Ministry of Infrastructure Development Al Bannai & Rushdi Cont co LLC Government of Umm Al Quwain UAQ 950 M 2 14 Electricity Authorit y Administration Building Ministry of Infrastructure Development Quba General Contracting FEWA FUJ 850 M 2 15 20 National Housing Ministry of Infrastructure Development Al Holy Group Government of Sharjah Sharjah 4,100 M 2 16 Shamal School Ministry of Infr astructure Development Al Nuaimi Group Ministry of Education RAK 8,500 M 2 17 secondary school Ministry of Infrastructure Development New Valley Building Contracting L.LC Ministry of Education RAK 8,500 M 2 18 100 National Housing Ministry of Infrastructur e Development Al Hamra Construction Ministry of Infrastructure Development RAK 18,500 M 2 19 Military Building Command of Military Al Geco General Contracting Command of Military RAK 3,800 M 2 20 Naval Military building Command of Military Al Geco General C ontracting Command of Military FUJ 3,750 M 2 21 Camping Command of Military AIMCO Command of Military RAK 3,900 M 2 22 50 National Housing Coengr Al Jazeera Civil Engineering Government of RAK RAK 1 0,500 M 2 23 Royal Miramar Resort Dimensions Travco Constru ction U K Holding Hotel FUJ 3,100 M 2 23 Accommodation Dimensions Nama Naguib Sawiris RAK 3,200 M 2 25 Water Tanks Dimensions Orascom Construction Naguib Sawiris RAK 3,400 M 2 26 Cave Rotana Resort Dimensions Orascom Construction Orascom Construction RAK 2 0,500 M 2 27 Administration Building Home of Architecture Core Instruction Kirby RAK 2,750 M 2 28 Khour Fakkan Port Government of Sharjah Warm Seas Government of Sharjah Khou fakkan 2,500 M 2 29 Consulate of Yemen Eng. Adnan Saffarini Office Bin Laden Consu late of Yemen Dubai 1,300 M 2 30 Commercial Building 10 floors International Engineering Consultant Two Construct Rashed Lotah RAK 2,500 M 2 31 Obaid Allah Hospital International Engineering Two Construct Government of RAK RAK 3,850 M 2

طرق العرض

- 4944 عدد المشاهدات

- 3859 موقع المشاهدات

- 1085 المشاهدات المدمجة

الإجراءات

- 0 مشاركات اجتماعية

- 4

- 0

- 0تعليقات

عدد المشاركات

- 0 فيسبوك

- 0 توتير

- 0 ينكدين

يتضمن 5

- 170 www.sab-us.com

- 22 161.97.92.48

- 8 161.97.92.48:8011

- 154 www.google.com

- 8

-

DCL مطابقة منتج مختبرات بلدية دبي

7904 الآراء -

We are all like same

3263 الآراء -

TRADE MARK Knights of Quality

3472 الآراء -

Knights of Quality

3571 الآراء -

The Egyptian Social Club, 6 October 2017

3419 الآراء -

-

Terraco UAE Ltd

3559 الآراء -

RAK Adhesive & Waterproof Materials

4551 الآراء -

Penetron Approval

3667 الآراء -

ستون من ذهب لصقر العرب

3795 الآراء -

SAB ISO 9001 2015 Certificate 2020-2021

4217 الآراء -

SAB PENETRON Approved Applicator Certificate

4354 الآراء -

SAB Trade Mark Certificate

5118 الآراء -

-

-

-

شمس البوادي - علامة تجارية مسجلة

5121 الآراء -

-

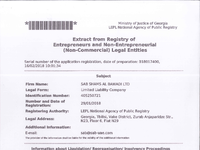

Shams Al Bawadi Georgia Legal Entitie

4199 الآراء -

მზე საქართველოს ხეობა უმეტეს ნაწილში ჩავვარდი

5076 الآراء

-

LAVATEX 2000

13356 الآراء -

الوقاية من الحرارة والرطوبة العزل المائي

8174 الآراء -

DCL مطابقة منتج مختبرات بلدية دبي

7904 الآراء -

Weber Product List

7806 الآراء -

-

Wurth sealants & Adhesives

7320 الآراء -

-

Optimization Methodology To Implement Thermal

7157 الآراء -

-

AWAZEL PU 250 White

6731 الآراء -

TDS-PC-221-EN_2319 (Plug Cement)

6599 الآراء -

طبقات نظام العزل كومبو رووف

6330 الآراء -

-

-

-

-

-

Fosroc Conbextra EPGP

5821 الآراء -

Dr. Fixit PVA BOND.

5725 الآراء -